Description

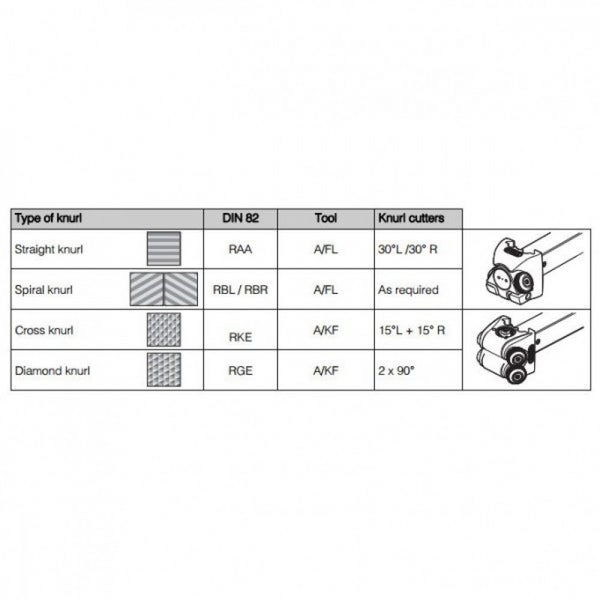

Cut Knurling Maximum precision and surface quality; it is even possible to knurl thin-walled workpieces with no deformation. Another advantage is the time saved due to the higher cutting speed and feed rate. Virtually any material can be machined, including grey cast iron and plastic. However, knurling to the shoulder of a workpiece is possible only to a limited extent. The A2/FL and A2/KF can be used as a left-hand or right-hand tool on the main and sub spindle of CNC and conventional lathes. A2 shanks 20x25, 25x25 can be used for the A2/FL and A2/KF tool bodies. The tool bodies of the A2 series are mounted using backlash-free surface clamping. The vibrations caused by the machining process are reduced by backlash-free surface clamping and can be dampened effectively. This prolongs the service life of the knurling wheel. Benefits: Reduced stock thanks to extreme versatility Compact size Simple and precise fine adjustment of the tool body: The diameter is easy to adjust using the double-sided index disc, irrespective of whether the machining is performed in front of or behind the turning centre, upside down or on main- and sub spindle. A backlash-free worm gear unit guarantees a simultaneous parallel contact of the wheel on the workpiece. Types of knurl: Straight and spiral Work piece: 5 - 250 mm diameter Shank diameter / L: 20x25 Knurling wheels: 21,5 mm diameter Straight knurl: 1 x 30 degree Left / 30 degree Right Spiral knurl; As required Machine type: conventional and CNC-controlled lathes. KNURL WHEELS NOT INCLUDED.

Details

Shipping & pick-up options

| Destination & description | Price | |

|---|---|---|

| Free shipping within New Zealand | Free | |

Estimated delivery times in business days

Seller does not allow pick-ups

Payment Options

Pay instantly by card, Ping balance or saved bank account.